welcome to Jiangyin Fine Chemical Machinery Co., Ltd. advisory hotline:0510-86501561/ 86501562/86501563

GWS high efficiency sand mill

Classification:

Product Description

worm gear type disperser structure

The new GWS high-efficiency sand mill adopts the newly developed sand grinding disc with guide groove to provide you with more efficient wet grinding process and technology. The high-efficiency guide groove grinding disc and super-large particle materials are thrown outside the filter screen, which not only protects the service life of the filter screen, but also makes the larger particle materials repeatedly grind in the grinding cavity, thus solving the problem that the filter screen is often blocked. The centrifugal wheel screen is used to increase the flow rate, and the grinding beads can be separated safely, high efficiency of separation even at high flow rates.

The system consists of the following units: a disc of the centrifugal guide groove, a specially designed centrifugal wheel, and a specially designed super-large area screen.

Application

Suitable for automotive coatings, coil coatings, anti-corrosion coatings, wood paint, screen printing oil, gravure ink, textile pigments, titanium dioxide, medicine, pesticides, etc.

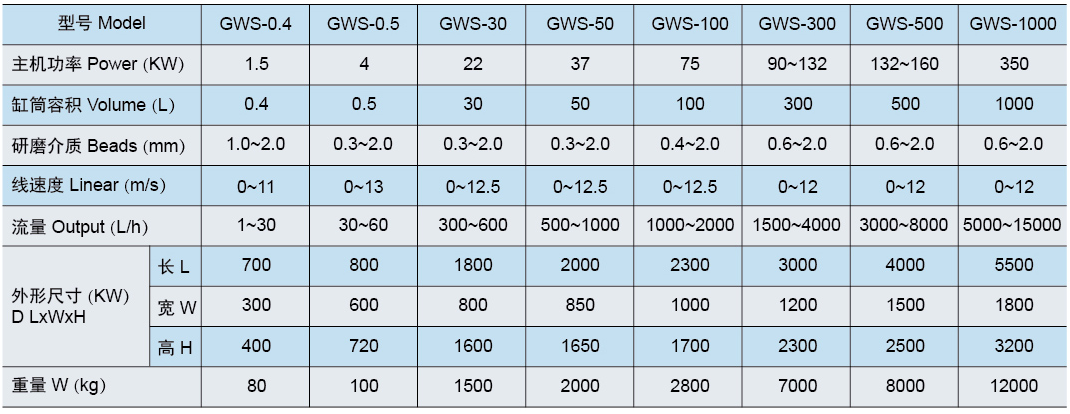

Technical parameters

Previous Page

Next Page

Product recommend

Welcome your message consultation

Contact Information

Address: 1490 Xicheng Road, Qingyang Town, Jiangyin City, Jiangsu Province

Hotline: 0510-86501561 86501562 86501563

Email: info@finemachinery.com

Zip Code: 214401

sweep

Browse mobile website

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Copyright©2024 Jiangyin Fine Chemical Machinery Co., Ltd.